Text ( 407) 288- 8353

TOP 5 AUTO LIFT MAINTENANCE TIPS

IF YOU HAVE A CAR LIFT, YOU KNOW HOW BENEFICIAL IT IS FOR CAR MAINTENANCE, STORAGE, AND OVERALL SAFETY. WHETHER IN YOUR HOME GARAGE OR AUTO MECHANIC’S SHOP, IT’S LIKELY YOUR MOST VALUABLE TOOL.

However, while many use the lift to perform vehicle maintenance, they don’t consider the need for regular maintenance on their car lifts.

It’s vital to perform regular lift maintenance, regardless of whether you’re lifting city buses or lifting ATVs. Otherwise, the car lift may malfunction, causing possible damage to the car and injury to you or your employees.

If you have a scissor lift, two-post lift, four-post lift, or in-ground lift, you need to perform routine lift maintenance for your employees’ safety and the vehicle’s protection.

Follow the top 5 maintenance tips below to keep your lift running smoothly. However, not all of these items will apply to your specific lift, so it’s a good idea to check your manufacturer’s manual for specific maintenance requirements.

1. Check the Lift’s Hydraulic System

The first thing you need to do is double-check the weight capacity of the auto lift. Make sure that you or your employees know the weight capacity and that you don’t attempt to lift a vehicle beyond the lift’s capacity.

Checking the hydraulic system includes a few things, such as checking the oil level and inspecting for leaks. If the lift needs additional oil, it’s an excellent time to add it.

In addition, you need to check for oil leaks, especially if you’ve noticed quickly falling oil levels, poor performance, or noticeable oil leakage under the lift.

You can quickly fix oil leaks by tightening fittings and couplings. However, if you have damaged hoses or seals, they will need replacing immediately.

Also, check the valves, hoses, and the hydraulic system’s overall function.

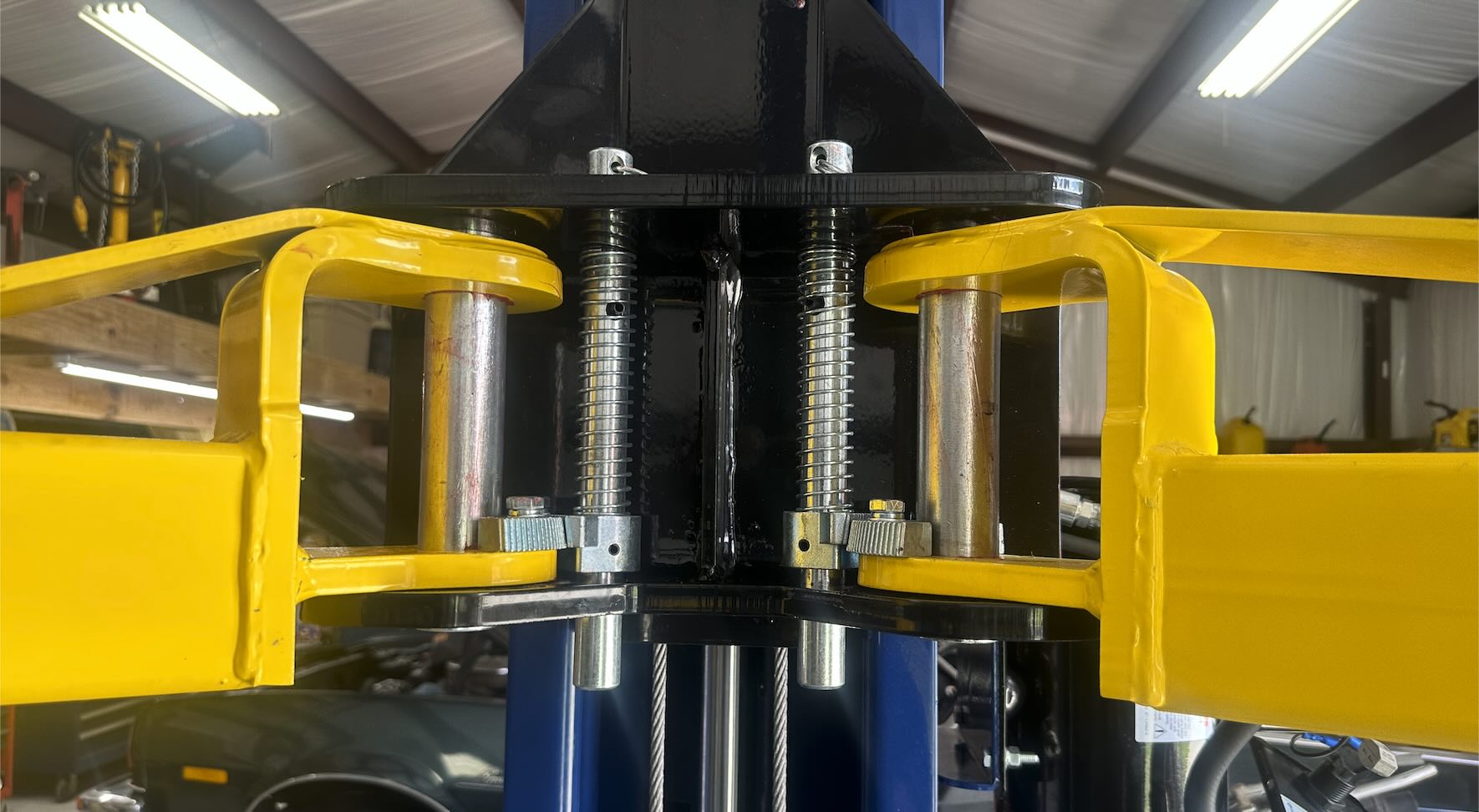

2. Check Chains, Cables, Pulleys, Spindles, and V-belts

When checking your chains and cables, the first thing is to ensure the chains, cables, and pulleys are adequately lubricated or greased.

In addition, you may need to adjust your cables because, over time, cables stretch. The lift may rise unevenly if a cable is not the proper length. Further, stretched cables can cause wear on other moving parts, such as the pulleys and shafts.

Also, once adjusted, ensure that your cables don’t move more than 1/2 an inch for two-post or four-post lifts.

Also, check for excess wear of chains, cables, pulleys, spindles, and v-belts. If anything needs replacing, it’s an excellent time to take care of that.

You need to replace cables every 4-5 years. First, however, you should have the cable replaced if you see or notice:

- three or more broken wires in one strand

- rusting or corrosion on the wires

- a cable core protruding

- any other abnormality

If abnormalities are found, shut down the lift immediately until the cables are replaced. Do not use your lift with any cables in question.

3. Check Columns, Posts, and Rolling Bridge

It’s essential to check for rust, damage, or wear and tear on your lift, especially the columns, posts, or rolling bridge.

Make sure to lubricate the necessary points on your columns.

You also want to check the alignment and ensure everything is set up correctly and in line.

Check for leaks on the rolling bridge and test the locks and rollers.

4. Check Electrical

While it may seem obvious, don’t forget to check the switches on the lift to ensure that they work appropriately and that the terminals are in good shape.

You’ll also want to check the limit switch for functionality, as a broken switch could allow your vehicle to run through the overhead beam on a two-post lift.

5. Check Overall Lift

In addition to checking the electrical and hydraulic systems and the columns, cables, and chains, you’ll need to inspect the overall lift.

Removing accumulated dirt, grease, or grime from your lift is essential to having a safe car lift.

Testing your lift is vital to ensure that all functions (top, bottom, full stop) work.

Ensure your lift’s decking and covers are secured, if applicable.

A loose anchor bolt could cause tremendous issues with your lift, so it’s imperative to ensure that the anchor bolts and other fasteners are tightened. Also, check the floor around the anchor bolts to see any cracks. If you have cracks near the bolts, you need to have an expert check out your lift immediately. While it may not be an issue, safety is of the utmost importance.

It’s critical to make sure that the swing arm restraints and telescoping stops are in working order, as they prevent the vehicle from rolling off the car lift when it’s lifted.

While you can take care of many maintenance tasks related to your car lift, some things should be left to a professional, including replacing hydraulic hoses, chains, rollers, cables, and sheaves. In addition, rebuilding or replacing hydraulic cylinders, pumps, or motors should be done by an expert.

Maintaining your lift is just as valuable as the lift itself. The lift can malfunction without proper maintenance, causing severe damage to the vehicle and injury to the lift operator.

All lifts are different, however, so not all of these tips will apply to your specific car lift. If you are unsure about maintenance on your lift, it’s a good idea to check your manufacturer’s manual.

Hopefully, this thorough guide has helped you learn how to do lift maintenance. Whether you’re an individual car hobbyist that uses car lifts to maintain and store your vehicle or a mechanic who uses lifts all day, SVI can help you.

We sell everything from new automotive lifts to components such as cables, pulleys, and hydraulic cylinders. So if you are an individual needing help finding the right part for your lift, or a mechanic who needs a rare accessory, we can help!